Hierarchical Task Analysis - A Perspective on Injury Prevention

Design and planning of work should be preceded by an analysis of the tasks to be undertaken. This is a systematic approach in which each step is analysed and can reveal the potential demands placed upon the worker and the system.

This can address potential scenarios given system / human failures such as critical tasks or emergency shut downs when the operator is under pressure or subject to adverse conditions.

Task Analysis (specification of physical and cognitive actions and the interactions with technology (Kirwain and Ainsworth, 1992)

Function Analysis (identification of transformations needed by the system to help users with their task)

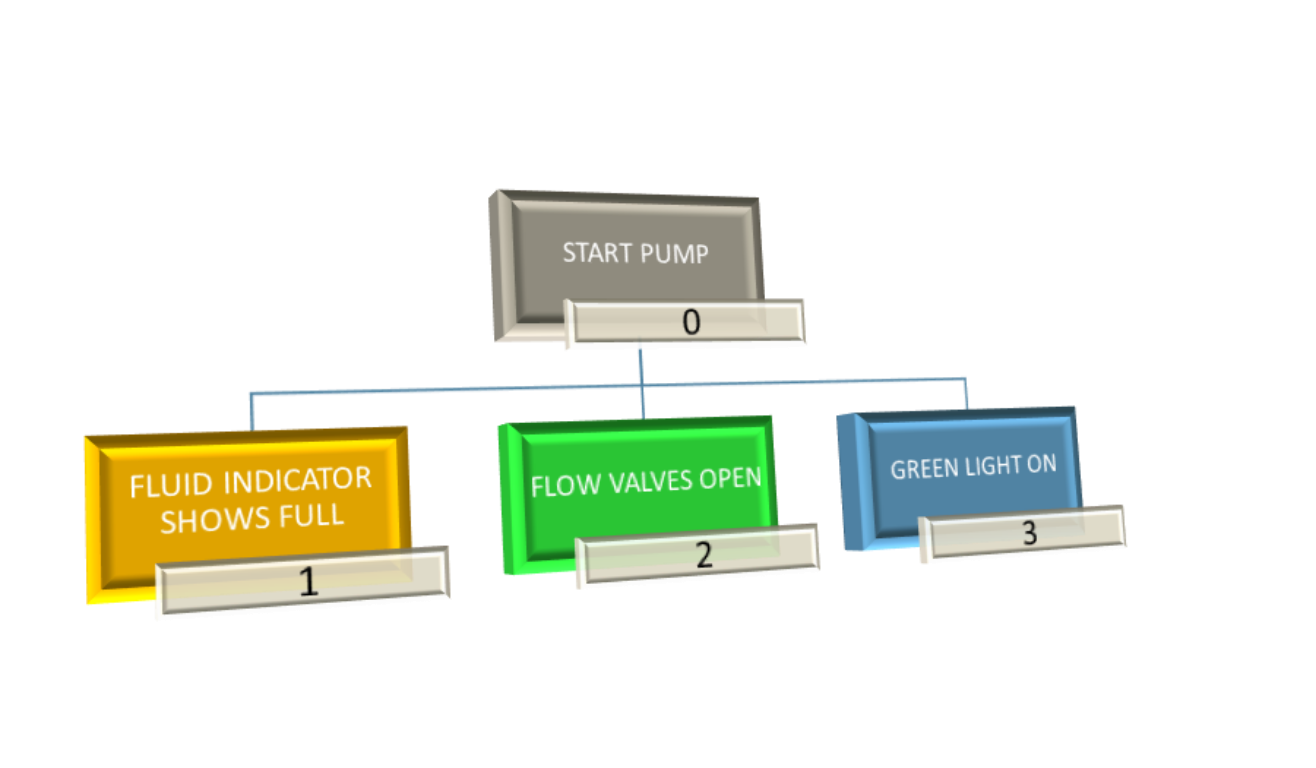

The Hierarchical Task Analysis was developed (1960) to show a greater understanding of cognitive tasks, involving significant components such as, predicting, decision making and monitoring. The aim of the analysis is to derive a sub-goal hierarchy for the task under scrutiny with several formats available including tabular.

Benefits include:

- assess crucial aspects of work

- design life cycle and relationship of equipment and people

- providing analysis and prediction of operator error

- detailed schematic assessment of operations

- inconsistencies between training and procedures

- transitional flow of information